If any later failure or damage occurs to the part, it must be determined whether it can still be used, or whether it should be repaired or replaced. Such decisions are simplified if there is access to the part's complete digital lifecycle data, and complementary analyses can be performed in order to improce the understanding of cause-effect relationships.

If a replacement part is to be manufactured, AM equipment that supports the original process plan and associated process parameters may not be available. If the part needs to be modified then a new process plan must be created.

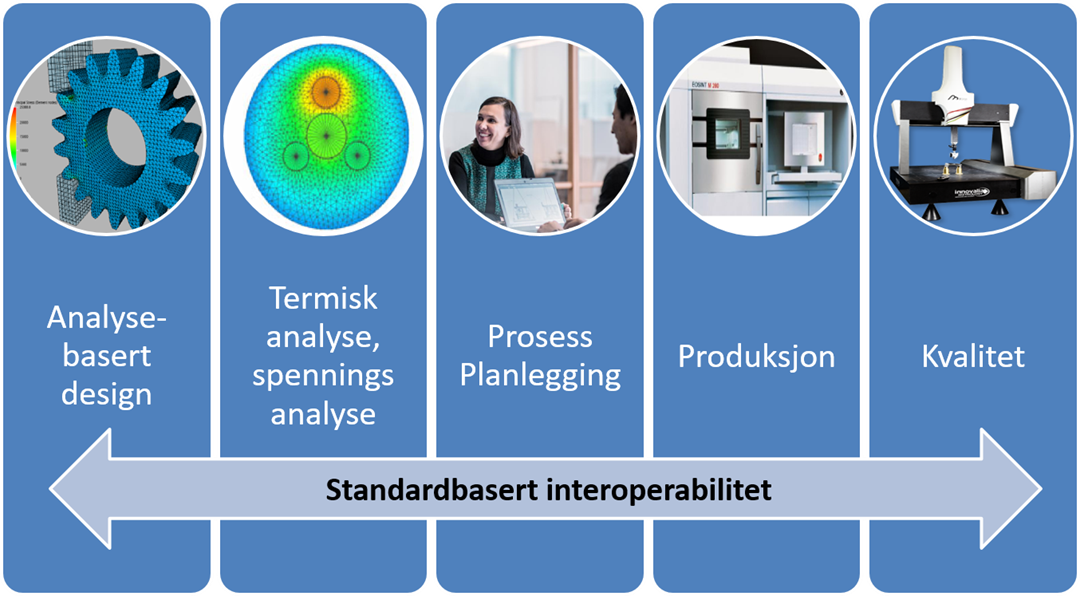

The path from idea to produced part (by AM) encompasses several different professions and digital systems, as indicated in the figure below. The digital systems must be able to understand each other, and the information should be readable regardless of the system that generated it. The use of information representation standards makes the information available for future use, and avoids locking in to a single provider of digital systems. It will be important to store the information in systems that store product data in a lifecycle perspective; Product Lifecycle Management (PLM) systems. Such systems make it possible to establish product-specific storage structures with configuration and version control. Information will be available when needed, for new analyses and new production runs sometime in the future. A PLM system will be a key component in a digital warehouse.