Our services:

Our knowledge about preparation of inorganic materials, mainly oxides, is used in projects where one wish to study new or established materials for particular applications. We have established extensive experience from various projects towards the international market. In SINTEF, we cooperate closely and interdisciplinary with issues involving synthesis, modelling and characterization of materials for particular applications.

We perform the following tasks:

- Crushing/grinding of raw materials for further processing

- Processing of powder to more applicable products by e.g. by using spray drying and agglomeration

- Preparation of advanced materials using wet chemical methods - either in powder form or as coatings, with controlled chemical composition and morphology

- Preparation of nano- and micro structured materials

- The powders may be further processed to e.g. membranes and components where the geometry, porosity and morphology need to be properly tailored

Method:

SINTEF has complete laboratories for materials synthesis and characterization. Typical forms of materials synthesis include flame spray pyrolysis, combustion methods, precipitation reactions, solid phase synthesis, hydrothermal methods and physical methods. Powders are spray-dried, granulated, agglomerated, coated, heat-treated and calcined using the equipment in our laboratories.

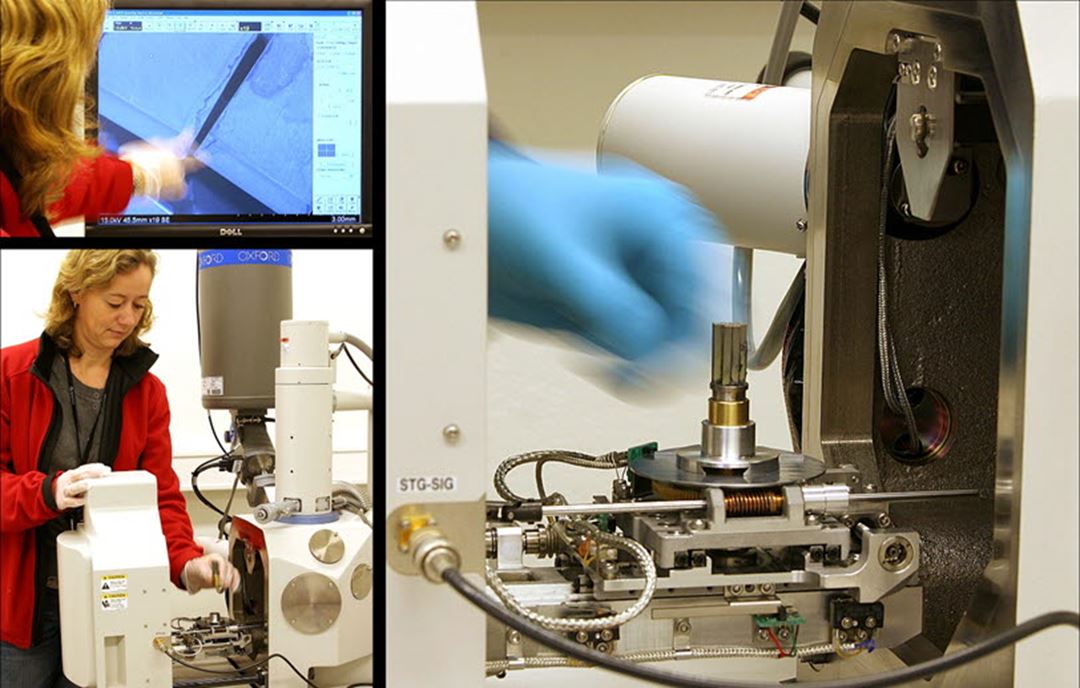

Characterization is carried out using e.g. electron microscopy, thermal analysis, x-ray diffraction (to examine purity of the material) and particle size analysis.

Typical assignments we are given:

- Preparation of advanced inorganic powder for further processing using methods that are possible to upscale.

- Fabrication/shaping of components, membranes, agglomerates and granules by powder processing

- Wet chemical processing where materials are deposited as thin and thick films on various types of substrates

- Chemical, physical and electrochemical characterization of materials

Contact: